Sources close to Hygiene Solutions Ltd. have revealed that the 45 minute deactivation phase of the Deprox cycle, which is claimed to bring the hydrogen peroxide level down to 1ppm, was recently doubled to 90 minutes.

This is a tacit admission that the catalytic deactivation units, added in great haste last year are hopelessly inadequate.

The change pushes the vaunted Deprox cycle time to over 3 hours – this is not competitive in the face of the Bioquell BQ-50, which for a typical side ward with ensuite (50m3) has a cycle time of just 1 hour 20 minutes. Given the cost of a hospital bed in the UK is about £400/day, this difference is very significant.

When Deprox was introduced, it had no catalyst whatever, and the hydrogen peroxide concentration when the room was re-entered was typically around 10ppm – ten times the legal limit.

As increasing evidence accumulated that Deprox operators were suffering serious respiratory damage, Hygiene Solutions endeavored to conceal the problem by turning down the amount of H2O2 the machines emitted. All Deprox machines were turned down to just 1/6th of the original H2O2 aerial concentration. This indeed left the concentration below 1ppm on re-entry, but of course it didn’t decontaminate the hospital room.

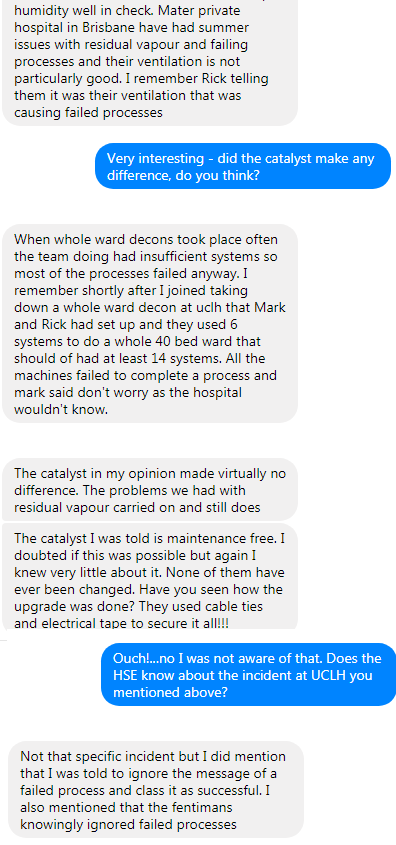

In early 2016, Richard Marsh who had worked briefly as a consultant for Hygiene Solutions Ltd, attempted to warn the NHS and the HSE of this highly dangerous practice, which was leaving 1000s of hospital rooms contaminated with C. difficile and MRSA across the UK, Australia and New Zealand.

Hygiene Solutions directors Rick Fentiman and Mark Fentiman of course categorically denied the claim, but hastily recalled all the Deprox units and retrofitted a crude catalyst, consisting of a commercial bathroom extract fan and a carbon palladium filter. According to a former employee, the catalyst was attached with cable ties and insulating tape.

These catalysts worked well when fresh, but quickly became hopelessly contaminated with dust and silver nitrate – their efficiency dropping to zero within a few dozen cycles.

Hygiene Solutions, ever innovative, came up with a new strategy. Where customers were using hydrogen peroxide meters to check the rooms before re-entry, the units would be turned down to the low 1/6th of nominal concentration. Where the customers were NOT checking before re-entry, they would leave the machines at the higher level. If one of these customers should complain of respiratory problems on re-entry, one of the directors would visit them with a “turned down” Deprox unit and an H2O2 meter, and demonstrate that the levels were within the safety limit.

In February 2017, Richard Marsh published “How to test your Deprox” This gave simple instructions to Deprox users whereby they could check the H2O2 concentration level that their machine was set to. This made Hygiene Solutions smoke and mirrors tactic rather risky – hence the recent decision to double the deactivation cycle time.

The conversation with a former Deprox operator reproduced below will give a taste of the utterly irresponsible attitude of the directors of the company.

And further…