“Men occasionally stumble over the truth, but most of them pick themselves up and hurry off as if nothing ever happened.”

Winston Churchill

Following the disastrous Addenbrooke’s test which revealed that the Deprox had a paltry sub-log2 performance in real hospital conditions, Hygiene Solutions decided that they would have to build a testing facility, hire a scientist and try to figure out what had gone wrong.

They were lucky to find an excellent and well qualified chemist, who had studied hydrogen peroxide for his thesis. This is David Sempere Aracil, with a Master’s degree in Chemical Engineering.

They were not so lucky with the test facility. The only space available was an unheated mezzanine in the D&H warehouse. Here they cleared a space amidst the veterinary sundries, and built a full scale hospital side ward in which to test the Deprox process.

The problem is that it was only full scale in the vertical dimension. In terms of length and width, it seemed wise to scale it down a bit, not only to save space, but also to make life a bit easier for the Deprox, poor thing, which was obviously struggling.

The Deprox is “validated” (to use a favourite word) for rooms up to 380m3, e.g. a 12 bed ward bay. A typical hospital side ward (single room with ensuite) is about 23m2 in area with a 2.8m ceiling height, giving a volume of 64m3.

The “side ward” as built is 1.5m x 1.5m x 2.8m. total volume 6.3m3 , just 10% of a hospital single bedroom, and 1.7% of the maximum volume that Deprox is guaranteed to disinfect.

It isn’t a ward, it’s a wardrobe.

David placed Log 6 biological indicator discs (Apex Biological Indicator #HMV-091) in 8 different locations around the inside walls of the wardrobe. Enter now the Deprox “Trusted by Leading Hospitals Around the World”. The process was run, and the BIs incubated – they were all alive.

David tried substituting Sanosil SO15 which at 7.5% H2O2 is 50% more concentrated than Deproxin. Now some of the BIs would be sterilised, sometimes. Over several weeks in late 2014, David did a series of 12 tests in the wardrobe, all with 7.5% H2O2 rather than the 5% Deproxin. He tried turning the ΔRH up and down, but to no avail. In 5 of these tests, all 8 BIs remained viable. None of the tests sterilised more than 6 out of 8.

David moved on to a more profitable job at the Ford Motor Company.

Rick Fentiman picked himself up and hurried off, as if nothing ever happened…

In summary then:

Deprox, running on a 5% H2O2 solution, is claimed to give a log6 decontamination of an entire 380m3 ward, including inside small crevices and complex equipment. In Hygiene Solutions own tests, the Deprox running on a 7.5% solution, and thus generating a 50% higher aerial H2O2 concentration than the standard process, completely failed to give a log6 decontamination of a 6.3m3 box in multiple tests.

Hygiene Solutions continued to promote and sell the Deprox with exactly the same claims, but around the same time that David left, they turned the whole Deprox fleet down from ΔRH20 to ΔRH5.

Fortunately, (or unfortunately for Hygiene Solutions) David’s notes of these tests survived.

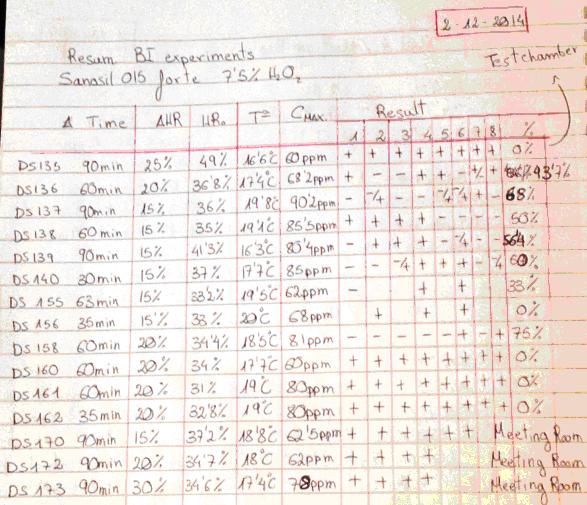

Explanation of table.

This table is a summary of 15 tests done by David Sempere Aracil, assisted by Tautvydas Karitonas, over a period of months. Both are university graduates with extensive research experience, and David has a PhD in Chemistry. The tests were done with a standard production model Deprox machine, the purpose of the tests was to determine if the extremely low efficacy of the Deprox process could be rectified by increasing the concentration of the hydrogen peroxide solution from the standard 5% to 7.5%.

The results were recorded in A4 hardcover notebooks of which there were at least 3. Each of the 15 tests was recorded in more detail on preceding pages of the notebook. In addition to the efficacy tests, the notebooks contain extensive details of tests on prototype catalyst systems, and constitute proof that HS was well aware of both the low efficacy and residual gas issues with Deprox.

Heading: “Sanosil 015 forte” refers to Sanosil S015, which is a disinfectant intended for water systems. It is 7.5% Hydrogen peroxide solution. Note that this is more concentrated than the 5% Deproxin solution that is used in production Deprox machines.

Col.1. The test number. These are not sequential, as some tests did not use Biological indicators (BIs) and were not recorded in this resume.

Col. 2 Duration of test measured from when the machine starts vapourising. (It takes several minutes for the machine to fill the piezo tank at the beginning of each test)

Col. 3 Delta HR setting of machine. This is adjusted by using unmarked pressure sensitive switches below the LCD display.

Col. 4 HRO This is the original relative humidity in the test chamber before the machine starts.

Col. 5 TO Temperature in the chamber before the machine starts

Col. 6 CMAX Hydrogen peroxide concentration in PPM, maximum level reached during process.

Results columns. The first 12 tests were done in the test chamber (wardrobe). Each number represents a specific marked location on the test chamber wall where an exposed stainless steel Bacillus subtilis log6 biological indicator was placed. The chamber is a crude wood and plasterboard structure in an essentially unheated warehouse. It is approximately 5’ x 5’ x 9’ and the indicators were placed at various heights on the interior walls of the chamber. The last 3 tests were done in the company board room which is approximately 12’ x 25’.

A” +” indicates that the BI still contained viable bacteria, a “–“ indicates that all bacteria on this indicator were killed.

Final column. This is the percentage of BIs that were killed.